The heat sink is a device for dissipating heat from the heat-generating electronic components in an electric appliance, and is mostly made of an aluminum alloy, brass, or bronze plate, sheet, sheet, etc.

For example, if the CPU CPU in the computer is to use a relatively large heat sink, the power tube, line tube in the TV, and the power amplifier tube in the power amplifier must use heat sinks.

Generally, in the use of the heat sink, a layer of thermal grease is applied on the contact surfaces of the electronic components and the heat sink, so that the heat generated by the components can be more efficiently conducted to the heat sink and then be dissipated into the surrounding air via the heat sink.

[design heat sink to note]

1, the greater the fin surface area, the better the heat dissipation effect.

2, if the fin is placed facilitate air circulation, the heat dissipation effect can be improved.

3, copper, aluminum thermal conductivity is good, is the preferred heat sink material.

4. Increasing the thickness of the heat sink is more effective than increasing the length.

5, surface anodizing treatment, can resist oxidation corrosion, improve radiation ability, stable cooling effect.

6, the economics of processing.

For example, if the CPU CPU in the computer is to use a relatively large heat sink, the power tube, line tube in the TV, and the power amplifier tube in the power amplifier must use heat sinks.

Generally, in the use of the heat sink, a layer of thermal grease is applied on the contact surfaces of the electronic components and the heat sink, so that the heat generated by the components can be more efficiently conducted to the heat sink and then be dissipated into the surrounding air via the heat sink.

|

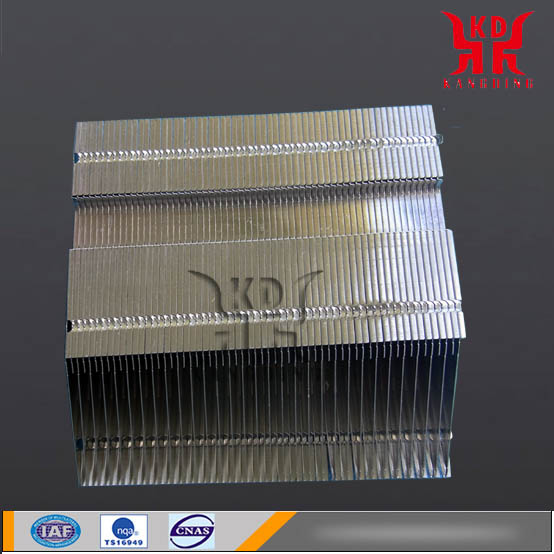

Metal stamping radiator fins

[Specifications] 115*136*3.0mm [Specifications] 115*136*3.0mm[material] Aluminum [process] blanking - punching - molding - cleaning - inspection packaging [Application scope] Radiator, play a role in heat dissipation [model] processing customization 【Characteristics and uses of heat sinks】 1, can provide the device with an effective volume of space. 2, can reduce the power loss of the device. 3, can improve the environment (the temperature around the device, and the air flow rate). 4. The maximum temperature allowed for the device junction. |

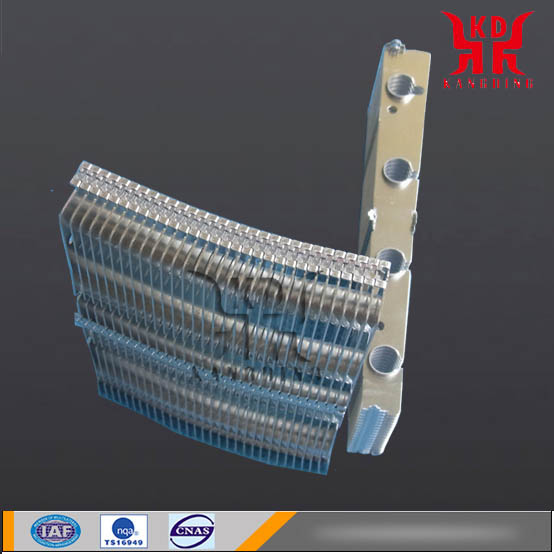

Power fins

[Specifications] 73*41.5*0.3mm [Specifications] 73*41.5*0.3mm[material] Aluminum [Process] Cutting - Punching - Tapping - Countersunk - Cleaning - Inspection Package [Scope of application] Electronic, computer, electrical equipment, play a cooling role [model] processing customization |

|

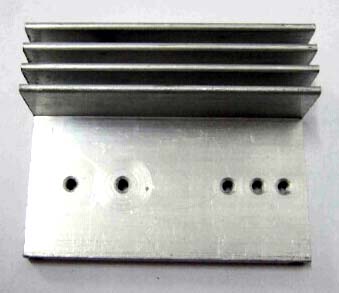

Heat sink kc301

[Specifications] 42.5*33.0*1.0(mm) [Specifications] 42.5*33.0*1.0(mm)[material] Aluminum [process] blanking - punching - forming - rivet PIN angle - cleaning - check packaging [Scope of application] power supply [Model] custom processing |

|

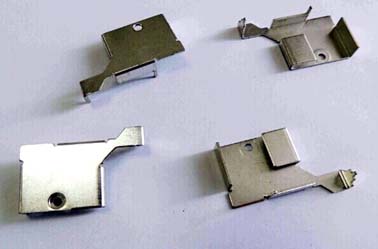

Tinplate heat sink

[Specifications] 73*41.5*0.3mm [Specifications] 73*41.5*0.3mm[Material] Tinplate [process] blanking - molding - inspection packaging [Scope of application] power supply [Model] custom processing |

|

Iron heat sink

[Specifications] 136*62*0.4(mm) [Specifications] 136*62*0.4(mm)[material] iron [process] blanking - punching - forming - plating - check packaging [Scope of application] power supply [Model] custom processing |

[design heat sink to note]

1, the greater the fin surface area, the better the heat dissipation effect.

2, if the fin is placed facilitate air circulation, the heat dissipation effect can be improved.

3, copper, aluminum thermal conductivity is good, is the preferred heat sink material.

4. Increasing the thickness of the heat sink is more effective than increasing the length.

5, surface anodizing treatment, can resist oxidation corrosion, improve radiation ability, stable cooling effect.

6, the economics of processing.